Red Hat blog

Like many long-standing companies, our fictional company Davie Street Enterprises (DSE) recognizes that its way of doing business must change. As outlined in a previous post, business today is done through processes that have been built at the company's inception, along with the tools that support those processes.

In this post, we will examine a major business process and the software tools that support it. Daniel Mitchell, the Chief Architect at DSE, will be leading this effort, addressing critical decisions(like build or buy) to support a successful transformation.

Old-fashioned ERP

The current application set is typical of an organization in the manufacturing industry. For this industry, inventory management or Enterprise Resource Planning (ERP) systems are perhaps the most critical. Ordering the right parts to make the widgets on schedule prevents manufacturing line delays. DSE is proud of its 90% rating for both meeting schedule and quality measures. This reputation helps DSE remain competitive despite its challenges.

The company’s ERP system is called Parts and Supplies (PAS). A home-grown system built by some of the first developers, PAS is the first software system the company started to use when software became popular. The original system was written in COBOL, but has been migrated and extended over time as a Java system.

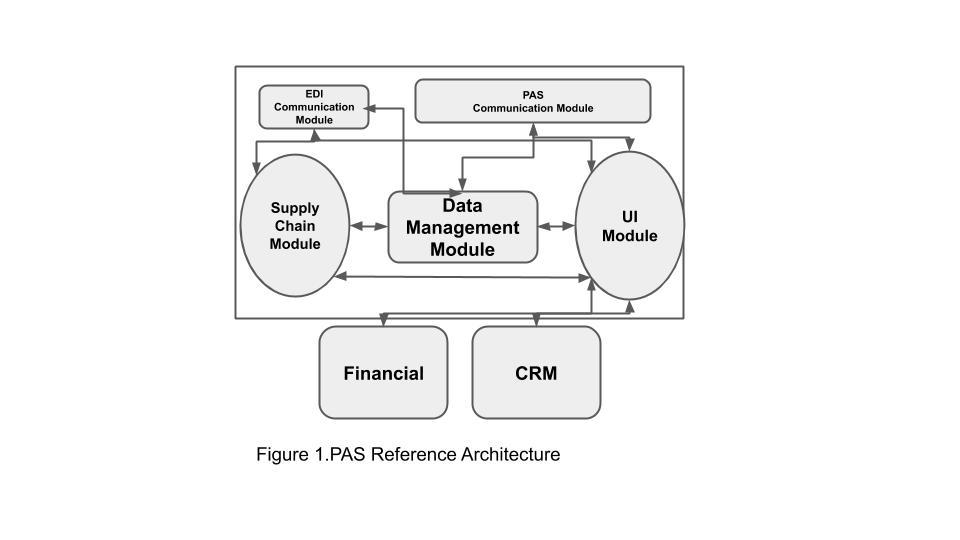

Its function is pretty straightforward. It’s essentially a process management system with a database of all the parts and suppliers, including the machinery that operates the plants. PAS also manages parts and supplies ordering and scheduling. It is made of several modules (see Figure 1) and has connections to other systems like the financial and customer relationship management (CRM) systems.

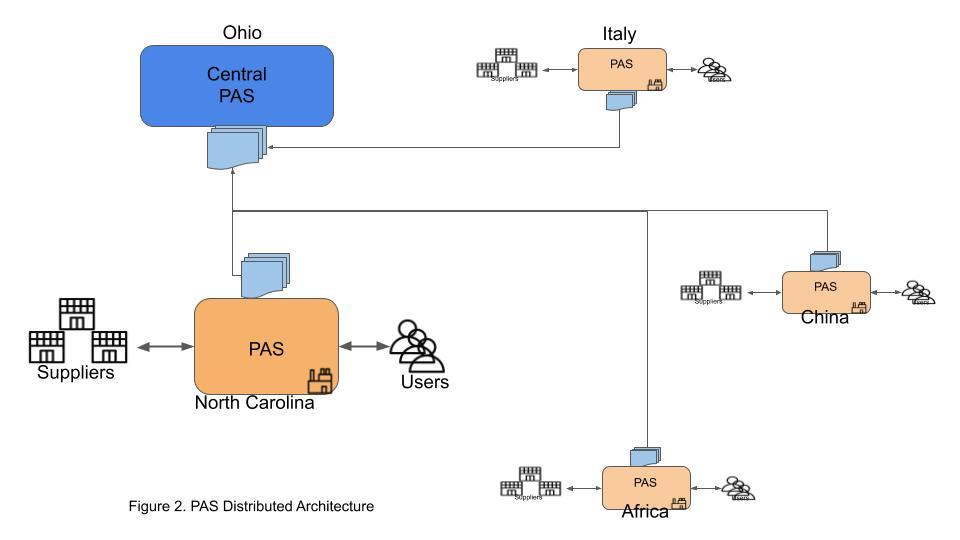

Each plant runs its own version of PAS. Each night, through a batch messaging process, PAS pushes updates and status to the central datacenter. As shown in Figure 2, Central PAS has an aggregation model that aggregates all the information and stores it. Although very functional, PAS has many problems.

The major problem with PAS is that it’s very brittle. It is a patchwork of extensions and fixes. There are parts of the system that are unchangeable because there is no one that understandthe code. So, there are lots of duplications and unnecessary patches throughout the code. It also contains massive customizations for each supplier and each plant.

PAS also requires many resources to monitor and maintain the system to meet the required SLAs. Without a reliable High Availability (HA) capability, the system crashes, often causing production delays that interfere with DSE’s rating. Over the years, the company has seen its rating decline from a 96% schedule and quality to 90%.

Lastly, DSE has great difficulty recruiting and maintaining high quality staff because the system is so old and difficult to work with. With this headwind, competitors with more modern systems can be a lot more nimble and have the agility to find opportunities with unsatisfied customers and suppliers.

To build or buy?

Faced with all of these challenges and more, DSE has several decisions to make. In order to help with these modernization decisions, it has done research with analyst firms and has even hired consultants that have provided a series of reports and recommendations. At the end of the day, it’s the leaders at DSE who have to make the ultimate decision.

Based on the recommendations and what they are seeing from their competitors, they know whatever the answer is has to merge with the pending cloud strategy. The choices and technologies have to play well into that strategy or it’s not going to work. So, cloud has to be part of the answer.

One of the biggest questions to come out of the research is: “Do we build it or buy it?” There are many Commercial Off The Shelf (COTS) ERP systems in the cloud or are cloud ready. However, it could take a $2.5 million investment (according to estimates) and at least 18 months to implement an off-the-shelf solution. There are maintenance and support contracts that will have to be considered on top of that.

From a resource standpoint, what happens to the team that develops the PAS system today? There wouldn’t be enough work to absorb them into the other application teams. DSE would like the PAS team to be an example of corporate modernization for other IT teams and groups as they begin the modernation journey. As the PAS team modernizes, it will provide DSE the opportunity to infuse it with modern skills and technologies.

With the decision to build complete, DSE needs to decide architecture, tools, and the appropriate implementation approach without totally disrupting the workflow. DSE wants to establish some core corporate standards as a part of the modernization efforts.

First of all, it must have a hybrid cloud architecture. This will help DSE to work in any cloud of its choosing. Some teams are having conversations with Microsoft, others with Amazon, and there are specific corporate functions and data that are not allowed outside of a corporate datacenter.

The other corporate requirement is that the architecture must allow for room to grow and expand. The system must support regional failover so that plants are operational at 99.049483% capacity. During implementation, the team must also rely on the automation strategy that has been recently developed, which will help make management of this new system much easier.

Finally, since this is a build, they should rely but not wait on the impending DevOps strategy. The implementation team should require the creation of a development and deployment pipeline, which may be able to pilot and inform the DevOps strategy as the new PAS system is being developed and deployed.

Considering open source

One other item that has come out of the consultant reports is the emergence of open source tooling as the wave of the future, leading the way for all technologies. Even if the technology choices include well known brands, those brands might be a few steps behind what the open source community can offer. As another corporate standard, open source technologies and/or vendors that develop them must be in any RFP discussions and decisions. Every technology that is being considered has an open source counterpart that must be considered.

Decisions, decisions

Finally, after months of deliberations, DSE has made some strategic choices to move forward and solve a lot of its persistent challenges. Based on the challenges and constraints placed on the leadership team, it has come up with a plan that will attract new talent, lay a path to move the PAS system into the future and provide much needed reliability and efficiencies into the process.

The new plan also paves the way for AI/ML processes that will allow DSE better forecasting ability and better insights into their current procedures. It will feed into the hybrid cloud and DevOps plans that are being currently defined. Let’s discuss the decisions that were made, show the architecture and the plan to get it implemented.

Red Hat was identified as the vendor of choice for two primary reasons. First and foremost, Red Hat is a leading open source company. Its portfolio of products span every tier of software, from operating system to process management to hybrid cloud platforms. Its entire portfolio is open source, which means it is tied into the latest open source software stack innovations.

Red Hat is also a recognized hybrid cloud provider. So, as DSE moves its platform into the hybrid cloud space, Red Hat can help guide it along the path. Red Hat has relationships with communities that are developing the latest development platforms and runtimes, which are desperately needed as DSE transitions away from the legacy PAS system.

Red Hat’s role in the new architecture

Let’s have a look at the re-architected PAS system that takes advantage of Red Hat technologies and services. This blog will focus on the application architecture rather than the hybrid cloud approach.

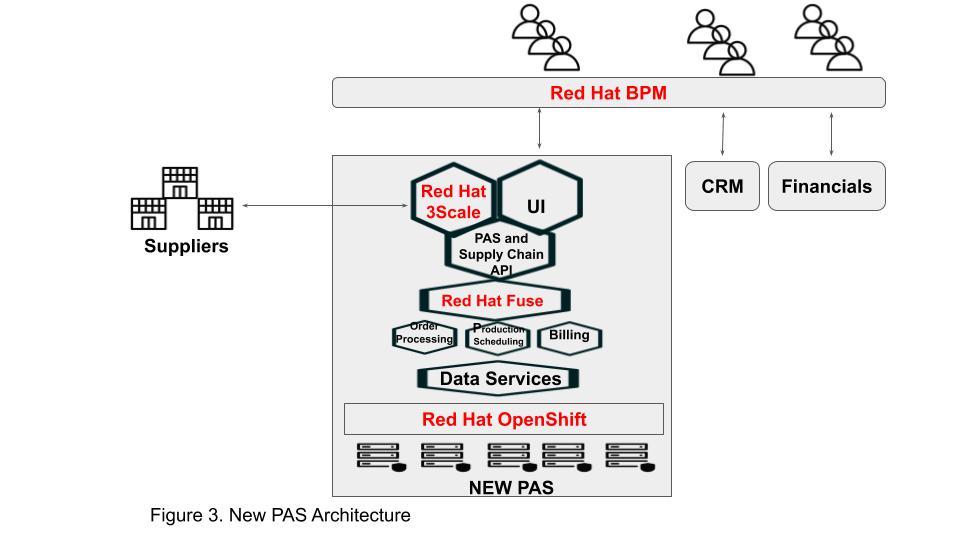

So, let’s get into it (see Figure 3 for the new architecture). As you can see, at the heart of it is the container orchestration platform Red Hat OpenShift. This platform provides the much needed autoscaling and reliability for the new PAS system. What also is seen in Figure 3 is that the system has been broken down into microservices. These services allow features of the system to be updated independently without being disruptive to other parts of the system, making the system much more manageable.

The services that were already java-based were just built as containers and used as is. The others were converted to java using Red Hat Quarkus as the runtime. Quarkus is the latest java runtime that is the smallest, lightest and fastest java ever. It keeps the services from being bloated, slow and memory-intensive processes.

In addition to Quarkus and Red Hat OpenShift, Red Hat Fuse was added to serve as the enterprise service bus (ESB). Its role in the architecture is to be a main line of communication between the services. This allows services to communicate with each other in the form and fashion that is best suited to meet their needs. Having Red Hat Fuse allows the New PAS system to have unchanged older services communicate with new services.

Red Hat Fuse has the ability to support and translate between many different protocols and communication formats. For example, this facilitates services that have messaging interfaces but need to communicate with services with APIs. Not only can it switch protocols, but it can also support message adapters that can convert messages accordingly. The ESB is a critical component, and Red Hat Fuse is already containerized and a supported open source tool that allows DSE to keep up with the latest in ESB technology.

To move up the stack, there is Red Hat 3scale API Management. The value that 3scale API Management brings to the solution is the ability to expose new PAS APIs to suppliers and other partners. This will allow suppliers to update order and status information directly into the PAS. This is much better than the former Electronic Data Interchange (EDI) process. EDI was old and outdated and not realtime. This will give DSE real-time visibility into the supply chain and allow for more dynamic decision making.

Finally, Red Hat Process Automation Manager was added to address DSE’s challenge of having too many manual processes that forced users to remember normal and exceptional process flows. Process Automation Manager will help automate ordering, billing and production scheduling workflows so users will not have to remember the workflow. Also, should the workflow change, the change happens in Process Automation Manager, and users are forced into the new process they were trained on.

Looking ahead

With these new Red Hat tools, DSE has positioned itself for the further development and the impending changes to the other systems. With the help of Red Hat services, these tools were implemented in a pilot with much success. Productivity improved by 45%. The system performance increased by orders of magnitude. In addition, the suppliers really like and are taking advantage of the real-time insights available to them as part of their internal workflows.

The transformation of Davie Street Enterprises is underway and off to a good start. The company has positioned its main application, New PAS, to be the lighthouse transformation project for the other applications such as the CRM system and financial systems. DSE was able to hire new skills interested in the transformation journey. This puts the company in a great position to continue onto the next steps of its digital transformation journey. In case you missed it, you can learn more about DSE’s modernization efforts here.

About the author

John Senegal is an ecosystem solution architect who works with strategic global partners to build joint and ecosystem solutions. His technology focus is around the AI/Ml and edge/ IoT partner ecosystems.