红帽博客

Within inventory management, perfect order refers to the ability to deliver the correct product to the customer, in the right quantity, at the right time, in the right condition, with the right documentation and at the right cost. Essentially, it means meeting customer demand without errors or delays to the highest degree possible. Inventory management encompasses procedures and processes that directly or indirectly affect the bottom line ordering, receiving, storing, tracking and accounting for all of the goods a business sells. It is a key element of supply chain management and is critical to any business that sells physical goods or is responsible for maintenance, repair and operations (MRO) supplies.

To achieve perfect order, a company must have an efficient inventory management system that optimizes inventory levels, tracks inventory movement and ensures accurate order fulfillment. This involves balancing the cost of carrying inventory with the cost of stockouts and lost sales, as well as implementing processes and technologies that enable real-time inventory visibility and accurate demand forecasting.

Achieving perfect order can help businesses reduce costs, improve customer satisfaction and loyalty, increase sales and maintain a competitive advantage.

The business challenges

Multichannel order fulfillment operations typically have inventory spread across many places throughout the supply chain, which requires visibility into what inventory you have and where it’s located. Businesses need an accurate view of inventory to guarantee fulfillment of customer orders, reduce shipment turnaround times and minimize stockouts and markdowns. Furthermore, inventory may not be on-hand or may be in a different location than expected.

Managing customer order is also not a binary "can ship or can’t ship" situation. Breaking shipments into multiple parts or making partial shipments may address many customer needs.

Spreadsheets, hand-counted stock levels and manual order placement have largely been replaced by advanced inventory tracking software. An inventory management system can simplify the process of ordering, storing and using inventory by automating end-to-end production, business management, demand forecasting and accounting.

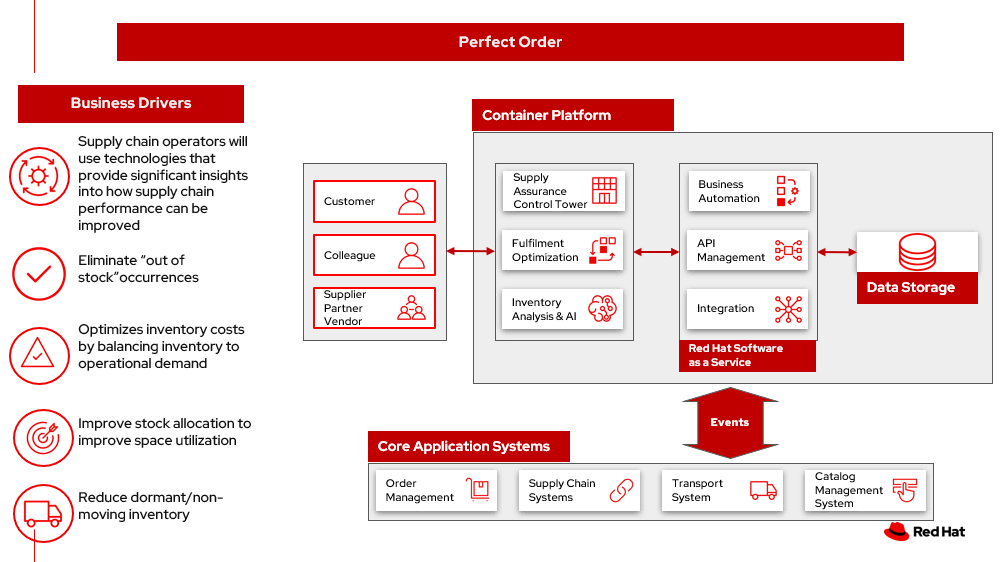

We’ll describe such a solution in the balance of this article. It has many benefits:

- Provides significant insights into how supply chain performance can be improved by anticipating anomalies in logistics costs and performance before they occur, and delivering insights into where automation can deliver significant scale advantages

- Reduces out-of-stock occurrences

- Optimizes inventory costs by balancing inventory with operational demand

- Improves stock allocation to improve space utilization

- Reduces dormant and slow-moving inventory

- Delivers an accurate assessment of critical spares and the money invested in those parts

- Increases transparency into and visibility of critical and non-critical spares inventory for the organization

- Reduces time spent looking for and ordering parts

- Accelerates disposal of obsolete materials

Solution overview

The solution shown below consists of three main categories: core application systems, foundational infrastructure and the inventory optimization platform. It embodies the following key principles:

True end-to-end visibility. Remove data silos and create a unified view across supply chain data with a standard data platform. Personalized dashboards and insights provide a 360-degree view of key performance indicators (KPIs) and significant events.

Manage by exception. Detect, display and prioritize work tasks in real time. This allows clients to sense and react to issues quickly while proactively managing risks and disruptions in a supply chain.

Intelligent workflows. Actionable workflows can be customized to meet unique requirements and process steps required to automate actions within source transactional systems. Make informed decisions with a supply chain virtual assistant that provides responses to issues based on a client’s supply chain data using natural language search.

Architecture

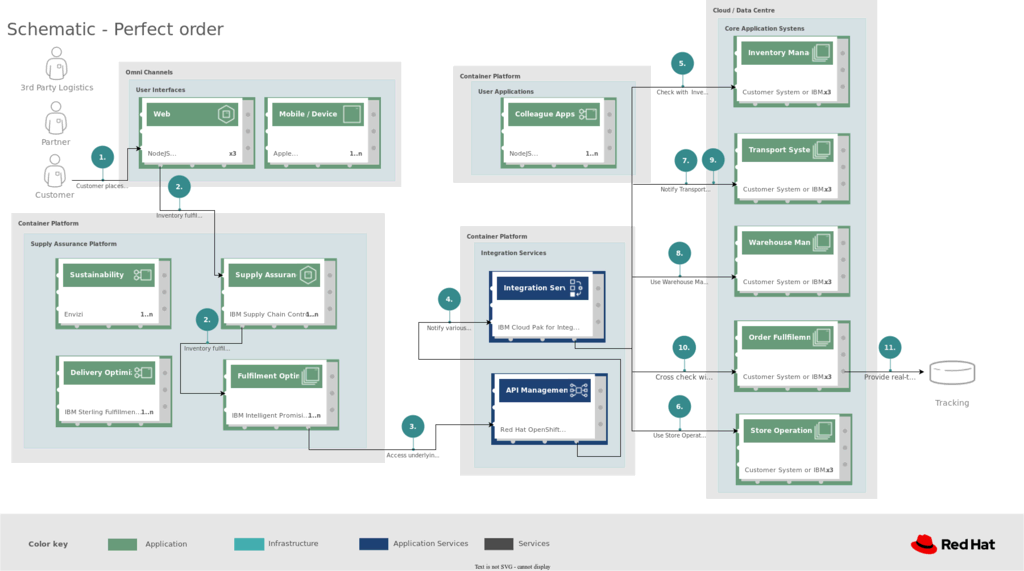

The following diagram shows the inventory management scenario for a perfect order solution that includes responses for cases where the order is not perfect.

The basic workflow typically begins when the customer places or otherwise interacts with an order through an omni-channel. Omni-channel refers to the integration of all channels and touchpoints that a retailer uses to interact with its customers, whether it is in-store, online, through mobile devices, social media or any other means. The goal of omni-channel retailing is to create a seamless and consistent customer experience across all channels, allowing customers to shop and interact with a retailer using the channel that is most convenient for them at any given time. Omni-channel retailing itself requires retailers to have a sophisticated technology infrastructure that enables real-time inventory visibility, order fulfillment and customer data management across all channels.

After the order is placed, inventory fulfillment and delivery tracking information is quickly obtained from the supply assurance platform with the backend system accessed via API Management and other backend systems accessed via the Integration Services. The Inventory Management System checks to see if the inventory is available and if it is, the items are locked and the inventory updated.

The Store Operations System then determines if the store can fulfill the order. If the store can only fulfill a partial order, it notifies the customer to determine if partial order fulfillment is acceptable. If acceptable, it then packages the order and gets it ready for delivery to the customer. The Transport/Logistics System is then notified to schedule delivery.

If a partial order is not acceptable, the system uses the Warehouse Management System to find which warehouse can fulfill remaining order items. An alert is sent to the warehouse to combine partial orders and package items and get them ready for delivery. Customers are notified and related systems are updated, including the Transport/Logistics System.

In either case, the Store Operations System cross-checks with the Fulfillment System to schedule and track the order in real-time and notifies the customer. Proof of delivery (electronic or paper) is provided to the customer.

Action Guide

From a high-level perspective, there are several main steps your organization can take to drive innovation and move toward a digital supply chain. For specific steps on this approach, see The Action Guide details in Own your transformation survey of 1500 CSCOs across 24 industries. It covers actionable steps in several areas of automation, sustainability and the modernization to hybrid cloud platforms.

Summary

In the digital supply chain, several systems work together to satisfy customer demand in cases where the items in the order are in-stock and available or when all items are not immediately available.

Perfect order encompasses a variety of other metrics that add up to a good customer experience from on-time delivery, to good quality, to appropriate packaging, to the correct invoice. Failure to get at least most of these things right, at least most of the time, cuts into profits and, perhaps more harmfully in the long-term, results in lower customer satisfaction and an erosion of brand loyalty.

If you are interested in more solutions built with these and other products in Red Hat's portfolio visit the Portfolio Architecture website and the Perfect Order Portfolio Architecture, in particular.

Supply Chain blog series

This blog is part of a Supply Chain blog series:

- Supply chain optimization imperative – Read the blog

- Supply chain optimization – See the blog and associated Portfolio Architecture

- Demand risk – See the blog and associated Portfolio Architecture

- Loss and waste management – See the blog and associated Portfolio Architecture

- Product timeliness – See the blog and associated Portfolio Architecture

- Perfect order – this blog and associated Portfolio Architecture

- Intelligent order (coming soon)

- Sustainable supply (coming soon)

关于作者

Bruce joined IBM as a Solutions Architect focusing on distribution and communication sectors in the industry market in 2021 in Client Engineering. Bruce has been a solutions architect since 2001. He led the initial cloud migrations to Microsoft Azure, managed research compute resources at Microsoft Research and built out Kubernetes implementations.

Karl joined Red Hat in 2021 as a Chief Architect focused on the Distribution sector. Prior to Red Hat, Karl was with IBM for over twenty-five years and served as the Chief Architect for the Retail and Consumer Industry in addition to other assignments. He is also an IBM Master Inventor.

Rajeev joined IBM Global Markets as an Account Technical Leader focusing on distribution and communication sectors in the industry market. Rajeev has been a Client Facing Architect for the last 17 years serving various organizations like IBM Expert Services Lab and IBM Global Services.