A fundamental goal for supply chains of physical goods is matching up available inventory with demand.

You can have too little of something (understock). During the pandemic, everyone became familiar with this scenario, whether it involved waiting months for a new car or scrounging all the local markets for toilet paper. These examples illustrate two of the ways in which businesses can fail to align with customer demand. In the case of automobiles, shortages in key components like microprocessors constrained what manufacturers could build. In the case of toilet paper, because people weren't in offices (and were maybe hoarding a bit) caused a spike in consumer demand.

But overstock is bad, too. Products or components sitting on a shelf or in a warehouse represent capital that’s sitting idle and some products can spoil if they sit for too long. This problem is most obvious in the case of food and other perishables, but it’s not limited to literal spoilage. Clothes can become last year’s style. The 2023 electronics gadget isn’t going to be worth as much once new models are announced at the Consumer Electronics Show the next year.

Business problem

Clearly, inventory optimization is a critical element of any organization's fulfillment process. It represents a balancing act between two key aspects of that process.

The first aspect is demand. The business needs to understand their current demand for products, goods and services—as well as forecasting their future demand.

The second aspect is inventory. The business needs to have a clear understanding of all the inventory held within their fulfillment system. An inventory management system provides oversight of current inventory and inventory changes due to purchases.

Inventory optimization is about making sure the current and future demand is accurately balanced against current and future inventory. Getting the balance right leads to a successful and profitable business. Getting the balance wrong leads to failure and, in the worst case, eventual collapse of the business.

Challenges include carefully managing inventory control, especially of high value and perishable items. Retail businesses with many locations also require managing inventory and the shipment of inventory at the store level. Forecasting, especially in light of events that cause unpredictable demand changes, is another challenge, as is efficiently handling overstocking and understocking when they inevitably happen in spite of your best efforts.

Meeting these challenges brings big benefits though. Faster inventory turnover leads to higher profits. Being able to meet customer demand improves the customer experience, which can lead to more sales and profits over time.

Let’s consider a solution that helps match up inventory with demand to handle understock and overstock events. The following summarizes a published Portfolio Architecture that diagrams and explains the solution in more detail.

Solution overview

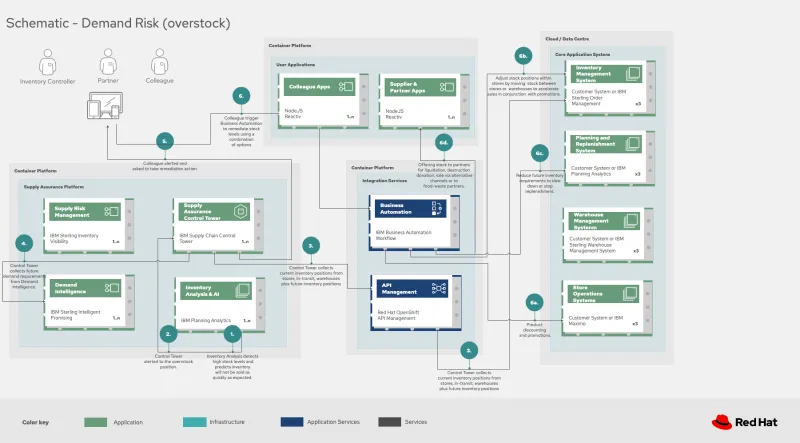

The solution uses the following technologies, which can be grouped into three main categories as shown in the diagram:

- Core application systems. These are often customer-provided technologies, such as order management and facilities management. These systems can include standalone applications, on-premises and cloud services, and databases.

- Foundational infrastructure. The Red Hat/IBM solution is built on Red Hat OpenShift with data routed through API management and events routed through business automation tools such as Business Automation Workflow.

- Inventory Optimization platform. This consists of a Supply Assurance Control Panel, Fulfillment Optimization, and Inventory Analysis and AI.

Understock and overstock workflows

The charts in this section demonstrate the interaction of customer systems with supply chain optimization platform systems in the context of a retail scenario with branch stores.

Understock workflow summary

When the Inventory Analysis block detects low stock levels and predicts inventory will become unavailable sooner than originally expected, it alerts the Inventory Control Tower to the understock position. The Inventory Control Tower then collects current inventory positions from stores, in-transit and warehouses plus future incoming inventory.

Inventory Control Tower also collects future demand requirements from Demand Intelligence. The “Colleague” (humans in the loop) is alerted and asked to take remediation action.

The Colleague now triggers Business Automation to remediate stock levels using a combination of options, including: ordering more stock, adjusting stock positions within the existing Supply Chain, managing inventory held at existing stores/warehouses and moving existing inventory as appropriate.

Overstock workflow summary

The initial overstock workflow is similar except, in this case, the Inventory Analysis detects high stock levels and predicts inventory will not be sold as quickly as expected and alerts the Inventory Control Tower of this fact. It then collects current and future inventory positions and alerts Colleague to take action.These actions can include moving inventory around, perhaps in conjunction with promotions and discounts.

Summary

Inventory optimization is making sure that current and future demand is accurately balanced against current and future inventory. Getting the balance right leads to a successful and profitable retail business. Getting the balance wrong leads to unhappy customers, reduced profitability and potential waste.

At a high level, there are several main steps your organization can take to drive innovation and modernize your supply chain relating to categories such as automation, modernization and sustainability. For specific steps on this approach, see The Action Guide details in Own your transformation survey of 1500 CSCOs across 24 industries.

If you are interested in more solutions built with these and other products in Red Hat's portfolio visit the Portfolio Architecture website and the Demand Risk Portfolio Architecture, in particular.

Supply Chain blog series

This blog is part of a Supply Chain blog series:

- Supply chain optimization imperative - Read the blog

- Supply chain optimization - See the blog and associated Portfolio Architecture

- Demand risk – this blog and associated Portfolio Architecture

- Loss and waste management (coming soon)

- Product timeliness (coming soon)

- Perfect order (coming soon)

- Intelligent order (coming soon)

- Sustainable supply (coming soon)

References

- McKinsey: How COVID-19 is reshaping supply chains

- Harvard Business Review: Three steps to prepare your supply chain for the next crisis

- Gartner: What is a Supply Chain Control Tower and what's needed to deploy one

- Gartner: Fulfillment Forecasting: The Key to Optimizing Retail Inventory Positioning

- Gartner: Supply Chain Risk Management (SCRM): What & Why Is It Important

- IBM Institute for Business Value: Own your transformation

- IBM Institute for Business Value: Balancing sustainability and profitability

- What is sustainability in business?

저자 소개

Bruce joined IBM as a Solutions Architect focusing on distribution and communication sectors in the industry market in 2021 in Client Engineering. Bruce has been a solutions architect since 2001. He led the initial cloud migrations to Microsoft Azure, managed research compute resources at Microsoft Research and built out Kubernetes implementations.

As a Chief Architect for Retail in the UK, Boyle engages in strategic dialog with IT decision makers and influencers across the ecosystem of Red Hat customers and partners. Boyle collaborates with architects and technologists across the globe to unlock the potential of open source solutions.

유사한 검색 결과

Data-driven automation with Red Hat Ansible Automation Platform

Ford's keyless strategy for managing 200+ Red Hat OpenShift clusters

Technically Speaking | Platform engineering for AI agents

Technically Speaking | Driving healthcare discoveries with AI

채널별 검색

오토메이션

기술, 팀, 인프라를 위한 IT 자동화 최신 동향

인공지능

고객이 어디서나 AI 워크로드를 실행할 수 있도록 지원하는 플랫폼 업데이트

오픈 하이브리드 클라우드

하이브리드 클라우드로 더욱 유연한 미래를 구축하는 방법을 알아보세요

보안

환경과 기술 전반에 걸쳐 리스크를 감소하는 방법에 대한 최신 정보

엣지 컴퓨팅

엣지에서의 운영을 단순화하는 플랫폼 업데이트

인프라

세계적으로 인정받은 기업용 Linux 플랫폼에 대한 최신 정보

애플리케이션

복잡한 애플리케이션에 대한 솔루션 더 보기

가상화

온프레미스와 클라우드 환경에서 워크로드를 유연하게 운영하기 위한 엔터프라이즈 가상화의 미래